Fashion and footwear industry in 2018 contributed to the world’s greenhouse gas emissions more than 8%, based on the Qantas report measuring fashion, which is almost the same amount created by heating, cooling or refrigeration itself (7%) or as much as the total climate impact of the EU-28. It is driven mostly by fossil fuel across the supply chain. The industry heavily relies on the non-renewable energy used in the manufacturing process. Additional burden is coming from raw material based again of fossil fuel products and also from manufacturing fashion, sport and shoe pieces.

Did you know that your clothes made of synthetic materials are made of non-renewable fossil-fuel oil?

Last few years topic about microfibers is grown while it was found they widespread around us.

Damage of fibres happens during manufacture, use, degradation and service (washing clothes) leads to generation of fragmented fibers also known microplastics or microfibers. The most abundant microfibres are from synthetic fibres mainly from polyester (PES) or rather polyethylene terephthalate (PET).

Did you know that 62% of clothes are made from synthetic materials?

The discovery of PET goes to 1930, and in 1941 the firs fibre was made. It was designed to last long. Really long, some hundreds of years. It was not designed to biodegrade. By time, the utilization of this material was extended from clothes to packaging of food, beverages or cosmetics, toothbrushes, and many other plastics of daily use. So, in last 80 years of using this material, humans were able to spread it everywhere around us, from salt water like Mediterranean Sea, Ocean, to freshwater, even to mountains like Mount Everest, soil through waste or in salt we use for cooking.

Did you know less than 1% of old clothing becomes new clothes?

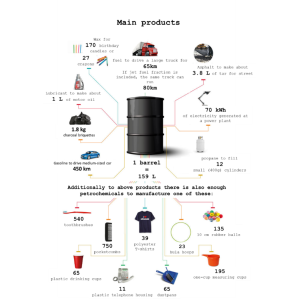

Also, the source of the raw material to manufacture PES or PET is hugely discussed because is made of fossil-fuel non-renewable source, the crude oil. What can be produced from one barrel of oil is given in infographics.

Clothes which we care for by washing and drying they mechanically rub of the tiny fibres, microfibers which they go to wastewater plant. Unfortunately, the smallest one will manage to pass and end up in our streams, rivers, lakes and sea.

But, laundry of mainly synthetic clothes alone causes 0.5 million tonnes of microfibres which is equivalent of almost three billion polyester shirts. Unfortunately, wastewater treatment plants often can not catch up to 40% of microfibers and hence, they can enter rivers, lakes, seawater and the ocean due to their small size, founded the team of microfiber pollution & the apparel industry project.

As an article published in 2020, microplastics reached new hights – they were collected from stream water and snow on the balcony (8,440 m.a.s.l) of highest mountain on Earth, the Mount Everest.

Source: Reaching New Heights in Plastic Pollution—Preliminary Findings of Microplastics on Mount Everest (Photo credit: Baker Perry/National Geographic)

Source: Reaching New Heights in Plastic Pollution—Preliminary Findings of Microplastics on Mount Everest (Photo credit: Baker Perry/National Geographic)

The team of scientists from the Ocean Wise conservation group published a new study on how Arctic Ocean being polluted with microplastics. The group documented the distribution of those tiny plastics in seawater from 71 station across the European and North American Arctic – including the North Pole. They found that most of them is polyester, 73%, which is almost three quarter of the micro plastic found. This research provides strong evidence that homes in Europe and North America are directly polluting the Arctic with fibers from laundry, throughout the wastewater discharge.

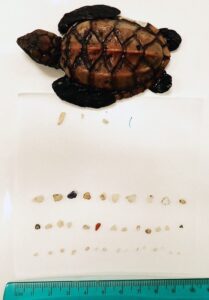

Based on many studies marine life and animal living there are struggling from this pollution of their environment. In 2020, team of scientists from Center for Marine Debris Research at Hawaii Pacific University in Honolulu found in hatched turtle 42 pieces of plastics in its stomach.

Source from study. Hatched turtle 9 cm long. Credit: Jennifer Lynch

So, the question is “Is it acceptable to us to end up eating plastic?” says UN Environment’s marine environment expert Heidi Savelli. “I think it’s a human right to not have to ingest plastic.”

“One of the problems is plastic ingestion at all levels of the food chain, which may pass plastic to larger animals and humans.”

Also, testing a sea, rock and lake salt, a total of 39 different salt brands from 16 countries/regions on six continents showed pollution with microplastics. None of us enjoys hair in the soup or main dish while being in restaurant. Correct? But on the other hand, nobody takes attention that salt we use for those delicious dishes may contain thousands of tiny plastics. Those we just don’t see, so, we don’t really care.

This is another example of call for the change.

- Looking for new raw materials which would replace the fossil-based raw materials – using biological origins as a raw materials like castor beans or turn end-of-life products into valuable high-quality and functional materials and/or products to reduce footprint to nature and boost circular economy. Example is recycling old car tyres to get material for further usage like vaude pants.

- Materials have to be designed and manufactured in the way that they create less peeling and less microfibres. The best is of course, zero microfibres or those they degrade – disappear in time.

- To have fibres they abrade less or if they do, then they are of based which does not accumulate or last too long. Example could be a wool fibre which is biodegradable and consists protein which does not harm environment. Also materials made of organic-based raw material (like castor oil, seaweed, sugarcane or fruit and food waste) called biopolymers or biosynthetic which they biodegrade.

- Design products that they can be regenerated including materials – biodesign – the future of conscious brand.

- Reduce number of different materials containing in one piece of product.

- Considering to change laundry habits makes definitely sense, it saves water needed to laundry, and energy for drying and ironing eventually. A guide is available here.

- Developing materials or other tweaks which would reduce creation of microfibers has the opportunity for growth.

- Polyester recycling – bring it back into supply chain could be one of the way. But it is not enough turning unwanted polyester clothes or bottles into valuable source for new products. It reduces demand mainly for energy but then does it really make sense to turn bottle into a newly designed clothes? Recycling reduces waste ending on landfill. But keep in mind the additional chemistry needs to be added which brings the functionality to clothes made of polyester and the quantity which is produced yearly is roughly 150 billion garments and 62% of them are from synthetic materials, and only 1% is recycled.