Many are asking this question when discussing about the wool and its performance. It seems not to be easy to accept that it is possible that one fibre delivers so many functional properties without any human contribution or innovation.

Wool has been developed over centuries and perfected by nature while worn next to the sheep or animal skin. The nature created very complex structure which provides wide range of properties. This unique feature attracts growing interest in using wool as a timeless, natural, and multifunctional fiber in sportswear, activewear, outdoor and travel clothing, and of course underwear. It is an all-rounder among all available materials.

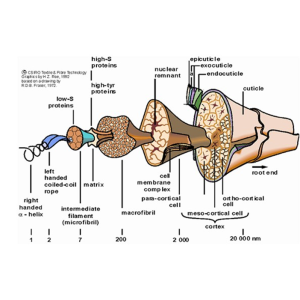

“Unlike cotton and the majority of synthetic fibres, wool does not have a homogeneous structure. Wool fibres have highly complex physical and chemical compositions that have evolved over millions of years to protect sheep from extremes of heat and cold.” – CSIRO.

This development of nature or rather evolution consist of natural membrane that is why wool is capable to response intelligently to outer and body needs.

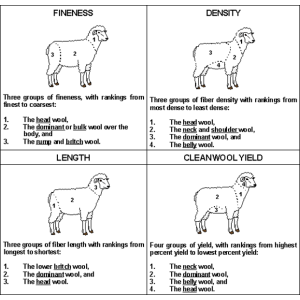

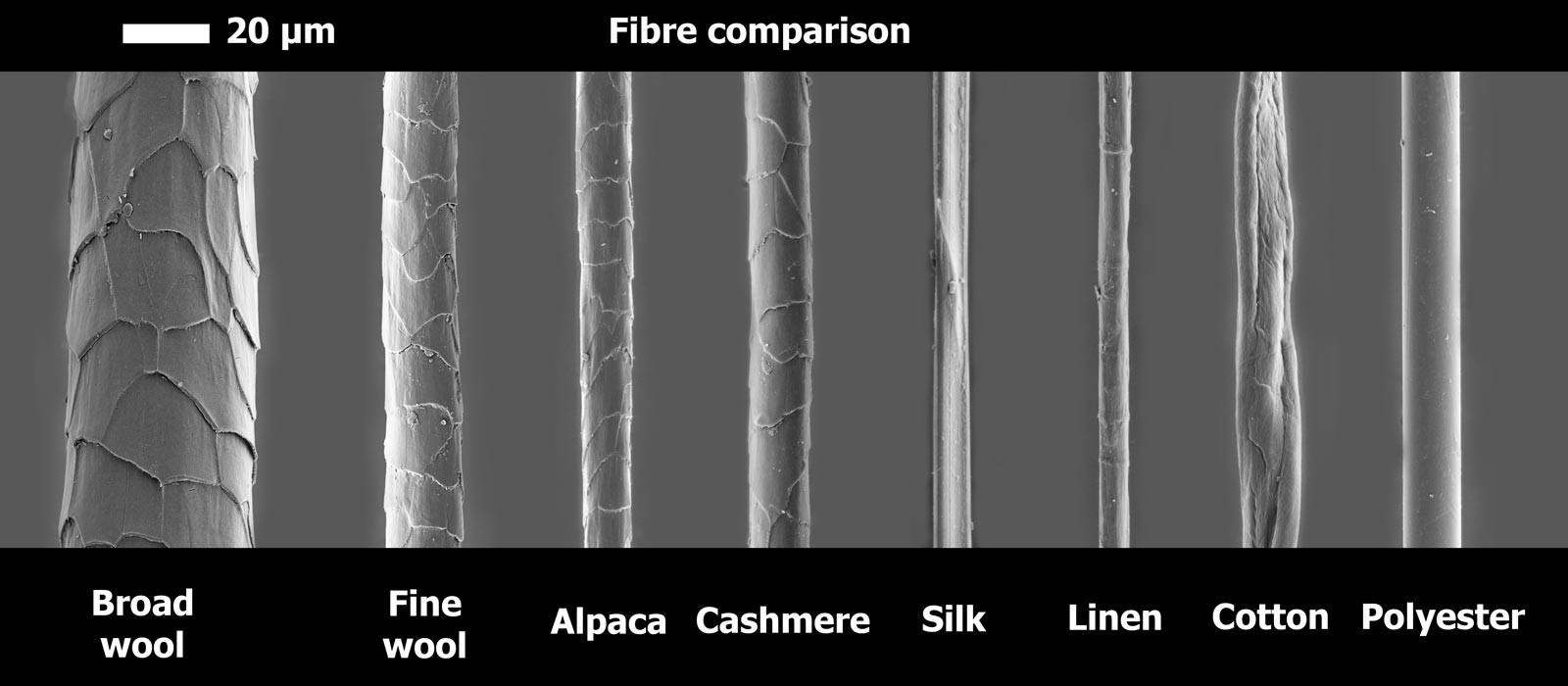

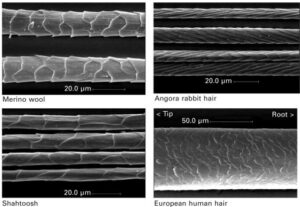

Fibre diameter refers to the ‘thickness’ or fineness of the fibre. Fine fibres provide soft-touch and bend easily. Course wool is more itchy and raw.

Cuticle scales are tiny overlapping scales, like fish scales, which surround the wool fibre. The cuticle scales can cause wool to felt – sometimes it is wanted to create thicker and wind proof cloths. Moisture vapour penetrates beneath the scales, allowing the fibre to ‘breathe’ or rather manage the moisture.

Epicuticle is one of the outer layers of the cuticle cells on the surface of the wool fibre. It repels liquids and resists abrasion which helps easier to clean.

Ortho and para-cortex form the core of the wool fibre. They arrangement causes the ‘crimp’ (wave) in the wool fibre and traps air (providing insulation) which leads to keep us warm and protected.

Cell membrane complex surrounds each strand of internal cortex – fibrils and holds them together. Absorbs colour which don’t fade.

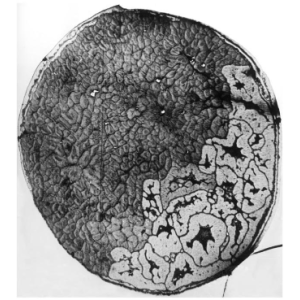

Above is transmission electron micrograph (TEM) of a 21 μm Merino wool fibre cortex – the inner part wool fibre consisting millions of cells bind together.

Macrofibrils and microfibrils are long filaments within the core of the wool fibre providing strength and resilience to the fibre. All wool products last therefore a long time, offering value – buy less to get more. More function. More quality. More sustainability. More nature. More circularity. More regeneration. More biodegradability.

Matrix (not the famous movie) consists of high-sulphur proteins which absorbs moisture to resist static and burning.

Alpha helix is the (kind of DNA) protein forming the helical coil thanks to which the wool fibre is flexible, elastic and resilient. In other worlds, durable – fibre lasts longer, and is wrinkle-resistant – it returns to its shape and therefore, muss not be ironed.

Wool fibre complexity is given by the number of proteins and amino acids in wool – 170 proteins and 18 amino acids. To make it simple, the main unit is keratin which is a natural protein (also in human hair). Keratin contributes significantly to elasticity and resilience of the fibre. It allows wool to stretch without breaking, bring it back into shape, and keep performing under extreme conditions. It biodegrades like the protein found in human hair and plays an important role in the composition of many related organic materials.

Source: Handbook of Textile Fibre Structure. Chapter 4: The structure and properties of wool and hair fibres

There is also wax or grease called lanolin. Lanolin is the coat or natural water-repellent treatment of the cuticle. Far better in terms of sustainability than the well-known PFAS. It protects sheep from the weather conditions and repels rain while allowing water vapour absorption. During wool processing, lanolin is washed off and extracted to create other wool by-product.

There are more than 1000 breeds of sheep around the world, which produce different types of wool, used for various purposes (Woolmark). This influences the quality and performance of the wool. For instance, there are recognised three main wool categories based on the fibre fineness – the lower the number of microns, the finer and softer the wool fabric:

- Fine – everything below 23.0 microns (μm) comes mostly from Merino sheep

- Medium – 23.0 – 29.0 microns (μm)

- Broad – more than 29.0 is specific for majority of sheep breeds

As motioned above, the finest wool comes from Merino sheep. Therefore, Merino wool has its own classification system:

- Broad Merino – more than 22.6 – 24.0 μm

- Medium Merino – between 20.6–22.5 μm

- Fine Medium Merino – between 19.6 – 20.5 μm

- Fine Merino – less than 19.5

- Superfine Merino – between 17.5 – 18.5 μm

- Ultrafine Merino – less than 17.5 μm

- Extrafine Merino – less than 15.0 μm